Today, Tuesday 5 November 2024, the John F. Kennedy Space Center in Florida saw the dramatic launch of a Falcon 9 rocket by SpaceX to the International Space Station (ISS) orbiting at an average altitude of 408 kilometres in low Earth orbit (LEO). At a cost of $52M, the SpX-31 commercial resupply mission is carrying a Cargo Dragon CRS-2 space craft, which will dock in the forward Harmony port of the ISS and deliver its payload, containing essential supplies for the astronauts and a number of experiments designed for operation in LEO.

The dramatic launch of a Falcon 9 reusable, two-stage rocket, designed and manufactured by SpaceX. The image shown is the CRS-30 commercial resupply service mission to the ISS, the Falcon 9 carried a host of supplies and integral equipment including science investigations and crew supplies. Image credit: courtesy of SpaceX, original image Ben Cooper.

Mission Patch of the SpX-31 commercial resupply mission to the ISS, representing a Cargo Dragon spacecraft, serial number C208, which is making its fifth flight on this mission. Image credit: NASA

The successful launch marks a significant milestone for the multidisciplinary research team led by Professor Ian Hamerton of the Bristol Composites Institute (BCI). It represents the culmination of over four years of intensive research to develop new materials for the space environment and the result of significant new collaborations between the BCI, the European Space Agency (ESA), the UK Space Agency (UKSA), the National Composites Centre (NCC), Oxford Space Systems, and Rolls-Royce plc.

In the late summer of 2020, ESA launched an international competition (AO-2020-EMA) to identify participants for a £3.5M Euro Materials Ageing mission to study the behaviour of new materials in space and BCI was one of 15 teams selected after a rigorous multi-stage peer review process. The Euro Material Ageing experimental platform (SESAME – Scientific Exploration Subsurface Access Mechanism for Europa), developed by the French Space Agency (CNES) and manufactured by COMAT, will be deployed by a robotic arm on the Bartolomeo platform designed and operated by Airbus (https://www.airbus.com/en/newsroom/press-releases/2021-01-esa-books-two-payload-missions-on-airbus-bartolomeo-platform), which is located on the front (the RAM face) of the ISS.

This mosaic depicts the International Space Station (ISS) pictured from the SpaceX Crew Dragon Endeavour during a fly around of the orbiting lab that took place following its undocking from the Harmony module’s space-facing port on Nov. 8, 2021. The red ringed area indicates the likely location of the SESAME module on the Bartolomeo platform. Original image credit NASA (jsc2021e064215_alt (Dec. 8, 2021), photograph taken by ESA astronaut Thomas Pesquet)

Preparation of one of the Euro Material Ageing’s experiments for launch. The COMAT designed SESAME module holds specimens selected and tested by ESA, supplied by 15 international research teams with the UoB samples shown in the inset image. Original image credit: Centre National d’Etudes Spatiales/COMAT.

Four new polymers, designed by Prof. Hamerton and developed within PhD projects in BCI, were prepared as carbon fibre reinforced composites and submitted to the ESA team at the European Space Research and Technology Centre (ESTEC) based in Noordwijk in the Netherlands for pre-flight tests. During these tests, the laminate samples were exposed to high vacuum and temperature cycling (to determine whether they would lose excessive mass in LEO) and to high intensity ultraviolet radiation (to find out whether they would discolour significantly, thus changing their thermal properties); fortunately, the specimens passed the pre-flight tests with flying colours.

The preparation of the composites on a much larger scale (typical panels measured 500 mm x 500 mm x 3 mm), to enable detailed mechanical tests to be performed in BCI, was funded by the UKSA (in the form of two grants ST/W000377/1 and ST/W004992/1) and undertaken by the team at the NCC. Although BCI has its own in-house autoclave and workshop facilities, when the pressure was on to deliver the precisely engineered composites to ETSEC with a short deadline the NCC was the natural choice of manufacturing partner. The development of the polymer matrices, the results of their exposure to simulated LEO conditions, and the mechanical testing have been published in a series of research publications (see further reading).

The novel composites will be in for a rough ride: the ISS will orbit the Earth some 6,000 times in a year at speeds of 17,000 miles per hour and the space environment is fierce, the temperatures could range from -150ºC to +120ºC, causing small cracks to form, and the samples will be exposed to high vacuum, severe electromagnetic radiation, and the ravaging effects of atomic oxygen which literally erodes the surface of materials that are exposed to it. It’s also crowded as there are already more than 8.8 kilotonnes of human-deposited mass in orbit. More than 30,000 space debris objects are larger than 10 cm, around 900,000 objects larger than 1 cm, 128 million pieces of debris around 1 mm, and 2 trillion pieces of debris around 0.1 mm. As a result, the specimens might also encounter high-velocity dust, micro-meteoroids, and engineering debris. To counter this, another line of current PhD research in BCI is developing variants of the same polymers that are potentially capable of healing themselves, with the aim of improving their ability to resist microcracking.

During the EMA campaign, real-time mass loss data will be collected to assess how the materials perform, and these will be used to validate analytical models currently being developed within one of the PhD projects to predict the lifetime of composites deployed in LEO. Prof. Kate Robson Brown, who leads the development of these computational models, has recently moved from the University of Bristol to take up a new position Vice-President for Research, Innovation and Impact in the School of Mechanical and Materials Engineering, University College Dublin, extending the collaboration still further.

She says “After nearly five years of research to develop novel composite materials for space applications it is very exciting to see our experiment launch to the International Space Station. I am proud to be part of this mission, and to be working with the mulltidisciplinary and multisector research team to deliver integrated real world and digital testing for innovative materials which will help to drive growth in the new space economy. This mission also demonstrates how space research funding creates career changing opportunities for early career researchers and PhD students in a sector of huge value to both Ireland and the UK.”

After a year or more of exposure in space, the samples will be returned to Earth, allowing scientists at BCI and in the other teams to thoroughly investigate the samples and fully understand the effects of the space environment on the materials, offering some validation of the newly-developed predictive models. However, the samples that have started their arduous journey to the ISS are not the end of the story. Virgil wrote, in his Aeneid, “sic itur ad astra”, thus one journeys to the stars, and the team is focused on the developing materials for the next generation of space travel. The BCI team is conducting research in another ESA programme (AO-2022-IBPER) to investigate the biological and physical effects of radiation on the composites, and team members have recently returned from a research visit to The GSI Helmholtz Centre for Heavy Ion Research in Darmstadt, Germany where the effects of long term galactic cosmic radiation (GCR) exposure can be simulated here on Earth. In another affiliated PhD project, polymer variants are being developed for their shielding characteristics towards GCR, inevitable in the longer space missions that are part of the plans of many space agencies, but potentially deadly to the future astronauts.

Research conducted on Earth under simulated exposure conditions is undoubtedly valuable but the opportunity to test the materials in the real proving ground of space is priceless and will help university scientists on the ground improve fibre-reinforced materials for next-generation space missions. The opportunity to participate in these high-profile ESA missions, with the generous support of the UKSA, has been an exciting dream come true for the academics and early career researchers in the team. By linking PhD programmes to the mission has offered the researchers at the very start of their careers the opportunity to be involved in cutting edge space research programmes.

The space materials team: L-R Gökhan Sancak, George Worden, Fabrizio Scarpa, Stuart Donovan-Holmes, Kate Robson Jones, Ali Kandemir, Ian Hamerton, Kyungil Kong, Mayra Yadira Rivera Lopez (members not pictured: Mark Schenk, Joseph Gargiuli, Yanjun He, James Thomas, Ragnar Birgisson, Lucas Lu, Galina Teshovska, Anton Stoger, Konstantina Kanari, Nick Hewlings, Alex Mathers).

The team gratefully acknowledges funding from the following bodies: ESA (AO-2020-EMA and AO-2022-IBPER), UKSA (ST/W000377/1, ST/W004992/1, ST/Z000343/1), the Engineering and Physical Sciences Research Council (EP/L016028/1 and EP/S021728/1), DSTL (DSTL0000020016) and Oxford Space Systems (in the form of a studentship).

The Teams

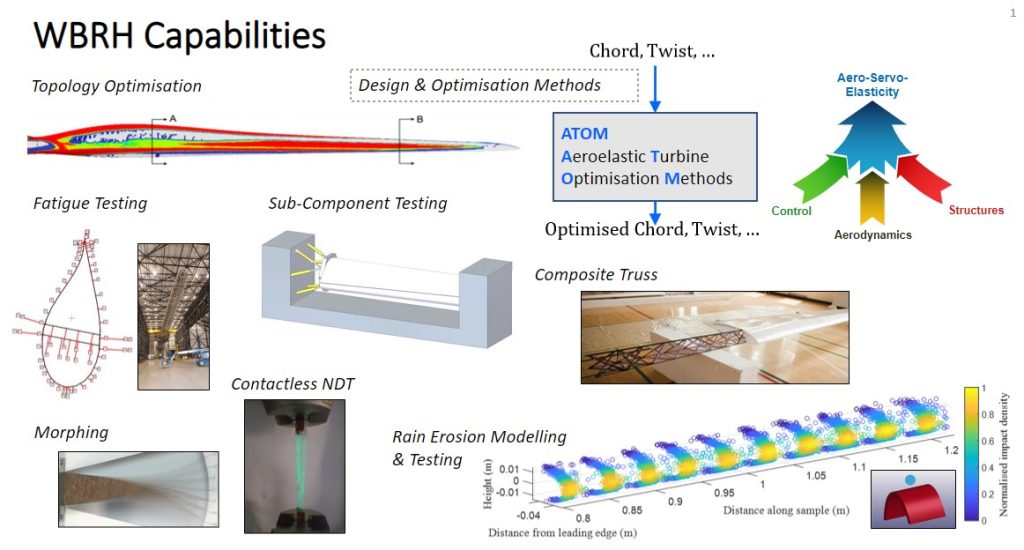

The Bristol Composites Institute (BCI) is one of seven Specialist Research Institutes of the University of Bristol and a world leader in composites research. Established in March 2017 in a dedicated £5.4M extension within the Faculty of Engineering, the BCI builds on the expertise and the 10-year track record of the Advanced Composites Collaboration for Innovation and Science (ACCIS) research group which preceded it. BCI has since grown to become the largest composites research group in the world; it boasts a world leading and cohesive core team of over 30 academics, 32 affiliated academic staff, 50 support staff, and over 150 researchers, and has world class experimental lab facilities enabling cutting edge research in advanced composite materials development, innovative manufacturing and design techniques, and composites testing. The BCI hosts the Rolls-Royce Composites UTC, the Wind Blade Research Hub, two EPSRC-funded Centres for Doctoral Training (CDT) in Composites, and the EPSRC Industrial Doctoral Centre in Composites Manufacture. Strong links exist between BCI and the National Composites Centre (NCC), which was opened in 2011 and is hosted by the University. The NCC is a not-for-profit research and training organisation which is an independent, open-access national centre translating world-renowned innovation into manufacturing excellence.

Space research and engineering is a well established at UCD, led by C-Space -Ireland’s leading centre for interdisciplinary collaborative space-related research, innovation and education. UCD has identified four key established and emerging trends as priorities; Foundational Space Research (addressing fundamental scientific mysteries of the universe, pushing the boundaries of pure knowledge and space exploration); Data-Driven Space Research and Innovation (applying AI, machine learning and data science to optimise space missions, accelerate scientific discovery and develop accessible platforms for EO programmes); Society, Ethics and Policy in Space (engaging with social sciences, business and law to address the societal, governance and legal implications of space exploration and commercialisation); Space Systems Engineering and Technology Development (advancing the design, development and deployments of space technologies including spacecraft, payloads and subsystems supporting space missions and the commercialisation of space).

Further Reading

Why Space? The Opportunity for Materials Science and Innovation, version 1.2.1, M. Lappa, I. Hamerton, P.C.E. Roberts, A. Kao, M. Domingos, H. Soorghali, P. Carvil (Eds.), STFC and UK Sat Apps, February 2024. (including Considerations for Material Development and Manufacturing in Space, Hamerton, I., Roberts, P. & Carvil, P. pp. 35-40).

Bristol researchers prepare composites for lift-off to space, Andrea Gaini, 8 July 2021, https://www.iom3.org/resource/on-course-sending-composites-into-space.html

University of Bristol, NCC develop novel composite materials to assess performance in space, G. Nehls, 7/7/2021, https://www.compositesworld.com/news/university-of-bristol-ncc-develop-novel-composite-materials-to-assess-performance-in-space

Effect of atomic oxygen exposure on polybenzoxazine/POSS nanocomposites for space applications, He, Y., Suliga, A., Brinkmeyer, AW., Schenk, M. & Hamerton, I., 2024, In: Composites Part A: Applied Science and Manufacturing. 177, 107898. https://doi.org/10.1016/j.compositesa.2023.107898

Physical and mechanical properties of nano-modified polybenzoxazine nanocomposite laminates: Pre-flight tests before exposure to low Earth orbit, Kong, K., Gargiuli, J. F., Kanari, K., Rivera Lopez, M. Y., Thomas, J., Worden, G., Lu, L., Cooper, S., Donovan-Holmes, S., Mathers, A., Hewlings, N., Suliga, A., Wessing, J., Vincent-Bonnieu, S., Robson Brown, K. & Hamerton, I., 20 Feb 2024, (E-pub ahead of print) In: Composites Part B: Engineering. 111311. https://doi.org/10.1016/j.compositesb.2024.111311

Development of cyanate ester-oligosiloxane copolymers for deployable satellite applications, Rivera Lopez, M. Y., Suliga, A., Scarpa, F. & Hamerton, I., 11 Dec 2023, (E-pub ahead of print) In: Polymer. https://doi.org/10.1016/j.polymer.2023.126573

Development of cycloaliphatic epoxy-POSS nanocomposite matrices with enhanced resistance to atomic oxygen, Rivera Lopez, M. Y., Lambas, J., Stacey, J. P., Gamage, S., Suliga, A., Viquerat, A., Scarpa, F. & Hamerton, I., 25 Mar 2020, In: Molecules. 25, 7. https://doi.org/10.3390/molecules25071483

by Valeska Ting

by Valeska Ting