by Dr. Laura Rhian Pickard.

This year’s European Rocketry Competition, held in Portugal, was a busy, chaotic and thoroughly enjoyable event showcasing technical achievements, and promising great things for the future.

Bristols’ HyPower team debuted a novel rocket, much of which was manufactured here at Bristol Composites Institute. In only one year the students have designed and built a rocket with a bipropellant liquid engine, which you can read about in their earlier blog post.

With only days to go before the competition, the team were given the opportunity to carry out a hot fire test of their engine at industrial partner Second Star. Initial flow trials were promising, but a collapse of the propellant tank spelled disaster. A quick change-around and installation of a backup tank brought hope- dashed when the problem repeated itself. This disappointment was keenly felt, but the team have identified the cause and are ready to improve the system- but it could not be done in time for this year. This exemplifies the theme of learning which has driven this year’s project.

Knowing we would not launch this time, the team set off for EuRoC anyway, determined to make the most of the technical advice on offer – and see what the competition are up to! UoB staff members Steve Bullock, Jack Marsh, Laura Rhian Pickard and Natalie Wiggins joined to support the team, meet EuRoC industrial partners and produce public outreach material.

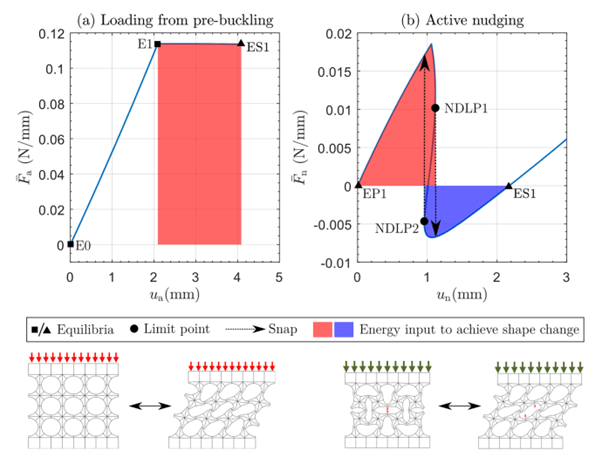

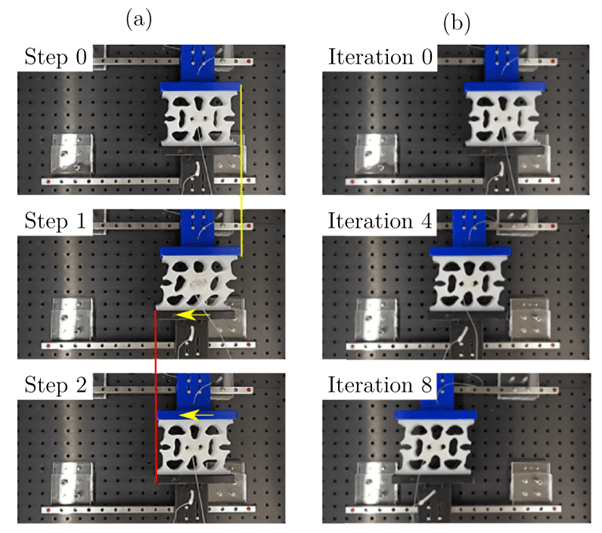

Composites were crucial for most of the teams, with some lovely rocket components on display. None could match the novelty of the ‘space sponge’ internal coupling developed by Bristol Composites Institute’s CoSEM CDT students. Linked to the NextCOMP programme which seeks to improve the performance of composites under compression by taking inspiration from the natural world, the students created a novel lattice structure coupling based on the skeleton of a sea sponge.

This coupling carries the payload bay, sitting just under the nose of the rocket, from where cubesats- or other payload- can be launched. The CDT students tested multiple cones of both the ‘space sponge’ and a baseline thin shell design under compression, the space sponge having approximately double the ultimate failure load of the baseline- a fantastic result. Testing at EuRoC revealed that it can comfortably support the weight of a Sicilian YouTube star. In addition to testing our structure, Etto Fins carried out an interview with team leader Lillian Macbeth for HyPower, and another with Steve Bullock and Laura Rhian Pickard discussing their respective research projects- including NextCOMP.

While the rocket could not fly this time, EuRoC was a valuable learning experience for the team- staff support included. The Technical Evaluation Board were most impressed with how far the team has come in a short time frame, with most teams taking many years to reach this point. There was praise for the rocket’s design- including a lot of interest in the ‘space sponge’. The Flight Readiness Review took multiple hours, where every aspect of the rocket was inspected in detail, simulations and design approaches were discussed and many interesting technical discussions took place. The experts and the HyPower team were confident that the rocket can be made ready to fly at a future competition- and came away full of ideas for the next generation of Bristol rocketry.

Meanwhile, rocket launches were happening! Despite the bright sunshine, high winds at altitude left many teams with a difficult decision- launch with only a drogue and no main parachute, accepting a hard and likely destructive landing- or do not launch at all. Multiple teams chose to take the risk and we saw some beautiful launches- plus a perfect demonstration of an abort for safety reasons- disappointing to the team in question but a successful launch nonetheless.

TU Munich’s team WARR rocket featured some lovely filament wound composite cylinders- and the first successful launch of a cryogenic bi-liquid rocket by a European Student team. Team Graz joined WARR with 3 awards each, Delft’s well named DARE group won one award, but the overall winners were team Skyward of Milan. Their rocket deployed a guided parafoil payload which steered to a gentle landing. Thanks to Agência Espacial Portuguesa, their industrial partners and all the teams for this amazing experience.

The HyPower student rocketry team have facilitated links between research groups within the Faculty and students on different courses. The ‘space sponge’ coupling demonstrates direct application of ongoing research, and plans for the next rocket include opportunity for a lot more of this- especially in composites.

We are proud of the work done by our HyPower team and the CDT students, and look forward to seeing a launch in the near future. Bristol students are amazing.

by Valeska Ting

by Valeska Ting