By Ege Arabul, Dr James Kratz & Dr Vincent K. Maes

Summary

A new research tool has been developed and commissioned at the University of Bristol, see Figure 1, to investigate the Automated Fibre Placement (AFP) deposition process. The machine, named “Real-Time AFP”, allows for composite pre-preg tape to be delivered onto a surface in an AFP/ATL-representative manner, where the process parameters, such as compaction force, temperature, speed and tow tension, can be varied, and the material tack can be characterised. The device also monitors the deposited tape and captures data in real time, allowing for the detection of manufacturing defects and correlation to the process parameters. The device aims to accelerate research into a wide range of AFP related topics, including novel sensor development, real-time control algorithms, and dedicated material benchmarking standard for AFP processes.

Figure 1– The newly commissioned Real-Time Automated Fibre Placement (RT-AFP) Machine in the Bristol Composites Lab (BCI).

Introduction

Automated Fibre Placement is a technique to deliver semi-finished, composite pre-preg tape onto a surface where narrow pre-preg slices are collimated on the head and delivered together through the use of a gantry head, heater, and a compaction roller. This technique is particularly well suited for gently curved or larger structures where a robust and repeatable manufacturing technique is needed, such as in aerospace applications, and where variable stiffness composites are needed such as in hyperbolic blended wing bodies, c-spars, and engine fan blades, which can be achieved through tow steering.

While automation of composite manufacturing processes has been successfully industrialised, part inspection and re-work remains a manual process, which can take up to 42% of the total time per build (Rudberg, T, “A Process for Delivering Extreme AFP Head Reliability”, 2019). Furthermore, this inspection is usually conducted only visually, which is highly dependent on the skill of the technician. Supplemented by the increasing trends in Industry 4.0 and a global emphasis on sustainability aimed to reduce waste and increase efficiency in composite manufacturing, methods to detect and react to defects during manufacturing are of great industrial interest.

The Key Features and Capabilities of RT-AFP

The in-house “RT-AFP” rig was developed to address the gap between the AFP representative lab experiments and the full-scale AFP deposition using a commercial AFP machine, which has varying degrees of process complexity, as shown in Figure 2. A key consideration in developing this machine was to ensure it provided rich, in-process deposition data, which many commercial AFP solutions would not offer for research purposes.

The key features of this machine include;

- Closed-loop control over AFP parameters, such as the layup temperature, compaction force, speed and tow tension.

- A real-time data capture system, including laser scanner profilometry data, to monitor the deposition process.

- Material tack characterisation capability via peel-tack-testing after deposition.

- Implementation of novel sensors in a modular manner.

- Ability to vary process parameters on the fly and implement different setpoint profiles.

Figure 2- Varying degrees of complexity in AFP research, with RT-AFP being in the middle.

Figure 3 illustrates the key components of the machine and its operating principles. The image on the left-hand side shows the loading of the composite pre-preg tape as it is being deposited. The pre-deposition and post-deposition laser scanners scan prior to and after the tape deposition, respectively, and can be used to subtract data from one another to identify the incoming tape and any misalignment or defects on the tape. After the deposition, the deposited tape can be peeled off by running the machine reverse.

Figure 3-The key components of the RT-AFP

Success Stories and Future Outlook

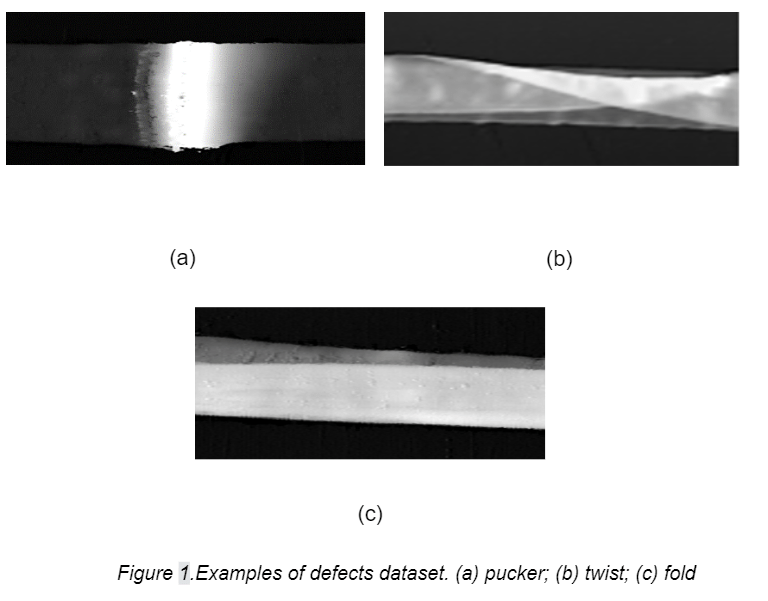

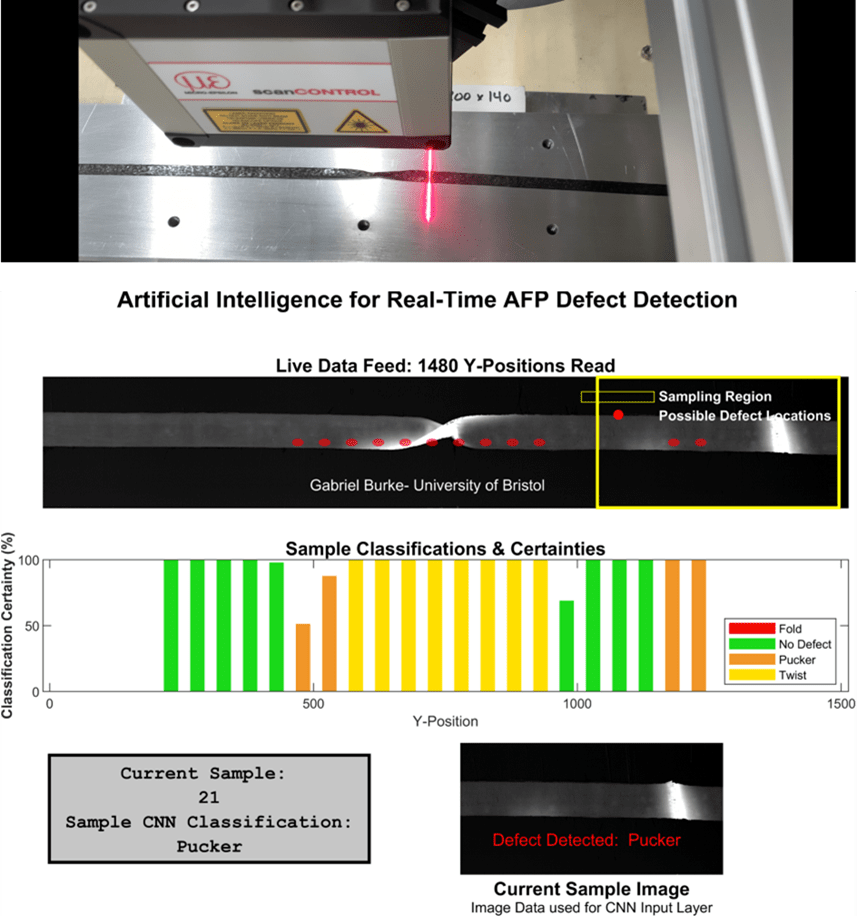

The “RT-AFP” has already been a critical resource for researchers investigating the AFP process. Some highlight studies include a comparison between the AFP and hot press processes for a layer-by-layer curing technology[1], a real-time defect detection system using laser scanners with convolutional neural networks to classify different types of deposition defects [2] and a real-time process control algorithm to mitigate influence of certain defects during deposition [3].

With strong ties to sensor development teams within the university, including non-destructive testing and evaluation, the “RT-AFP” is a growing tool to accelerate research. Along with these studies, the device is also being used to correlate the process parameters to the evolution of AFP manufacturing defects to better inform our understanding, and models of the AFP deposition process and to develop novel techniques to eliminate arising defects on the fly. The research team invites future collaborators investigating the AFP process, within and external to the university, to utilise the machine to accelerate their research capabilities.

Figure 4-Summary of key success stories using the RT-AFP

Linked Articles:

- Hartley, R., & Kratz, J. (2024). CFRP layer-by-layer curing using research-based automated deposition system. Manufacturing Letters, 40, 85–88. https://doi.org/10.1016/j.mfglet.2024.03.005

- https://composites.blogs.bristol.ac.uk/2023/11/30/real-time-quality-control-in-automated-fibre-placement-using-artificial-intelligence/

- Nguyen, D. H., Sun, X., Tretiak, I., Valverde, M. A., & Kratz, J. (2023). Automatic process control of an automated fibre placement machine. Composites Part A: Applied Science and Manufacturing, 168, 107465. https://doi.org/10.1016/J.COMPOSITESA.2023.107465

In parallel, development of fibre steered composite structures, led by Prof. Byung Chul (Eric) Kim, has had several successful steps towards commercialization. Specifically, a recent

In parallel, development of fibre steered composite structures, led by Prof. Byung Chul (Eric) Kim, has had several successful steps towards commercialization. Specifically, a recent

A group of Sixth Form students are being taking part in the NextCOMP Crusher activity, guided by a current CDT student. Photo credit: James Griffith

A group of Sixth Form students are being taking part in the NextCOMP Crusher activity, guided by a current CDT student. Photo credit: James Griffith A group of Sixth Form students engaged in the activity of creating an aeroplane wing. Photo credit: James Griffith

A group of Sixth Form students engaged in the activity of creating an aeroplane wing. Photo credit: James Griffith A group of Sixth Form students testing their Marble Run. Photo credit: James Griffith

A group of Sixth Form students testing their Marble Run. Photo credit: James Griffith