Fabrizio Scarpa and Adam Willis Perriman

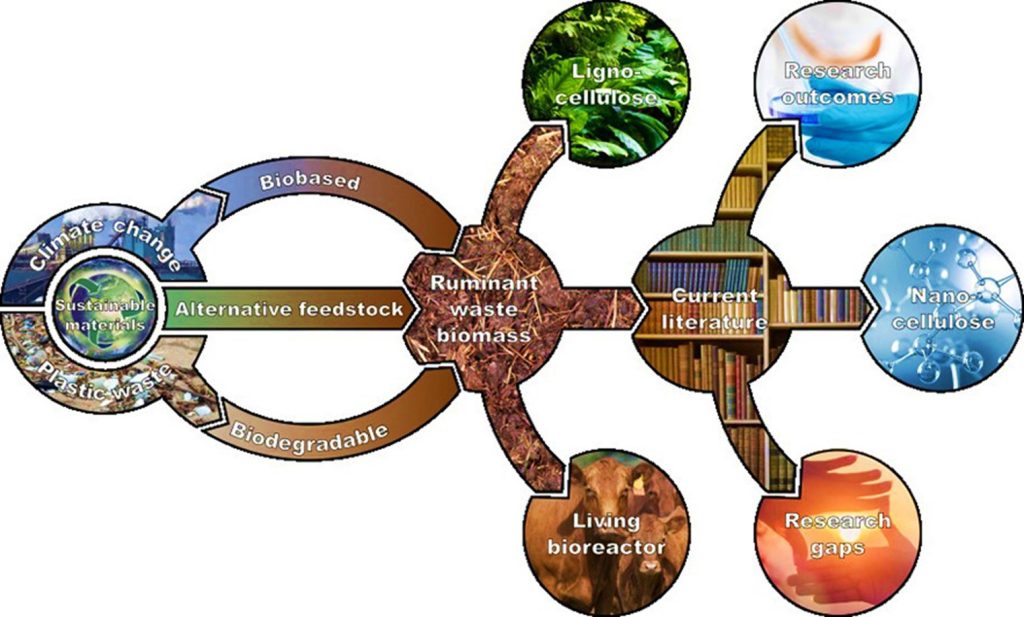

A recent review work carried out at the BCI in collaboration with the Scotland’s Rural University College and the University of Edinburgh has identified several routes to obtain crude biobased materials, composites, and purified derivatives from manure. The paper is open access and can be found here: https://www.sciencedirect.com/science/article/pii/S014181302300404X?via%3Dihub

Manure can be considered as an unlikely source of biomass. It is rich in lignocellulose components like cellulose, hemicellulose, and lignin. Renewable biomasses provide a global yield of 200 billion metric tons per year of lignocellulose, yet the separation of the biobased components requires a combination of energy-intensive physical and chemical processes.

Herbivores (and ruminants, in particular) have however highly developed digestive organs able to break down the lignocellulose. Lignin reinforcements obtained from cattle dung have shown a very promising performance in terms of matrix adhesion to phenolic resins. The digestion process of ruminants like cows contributes to an enhanced surface structure of the biobased fibres, which favours bonding with different matrices.

A similar enhancement of bonding between phenolics and reinforcement obtained from elephant dung is not however present. Elephants are monogastric and lack the foregut fermentation that cows provide. The diversity of the bio chemo-physical origins of animal manure therefore constitutes a challenge to manufacture composite materials with unique production processes. Nevertheless, composites made from animal manure components are mixable with a wide variety of thermosets and thermoplastics, making them appealing for secondary load-bearing applications across the industries.

Quite significantly, manure could be used to extract nanocellulose, which it has a huge potential for use in a wide variety of applications, from structural to antibacterial agents, fuel cells, and biomedical applications. Current production methods of nanocellulose are energy intensive, while the use of enzymes in biomass has been hailed as a low-cost methodology for production. Animal ruminants and in particular cattle can provide an alternative way to produce at larger scales nanocellulose and other lignocellulose-based components, because we can make use of the existing large-scale supply chain in the agricultural and livestock business existing in the UK and beyond. Never has the old saying: “Where there’s muck, there’s brass” sounded truer.”