One of the larger activities currently happening at the Bristol Composites Institute is CerTest. This EPSRC (UK Engineering and Physical Sciences Research Council) Programme Grant, with £6.9million of funding, started in July 2019 and will run for 5 years.

CerTest is led by Bristol Composites Institute Co-director, Professor Ole Thomsen at the University of Bristol, with academic collaboration partners at the University of Bath, University of Exeter, and University of Southampton.

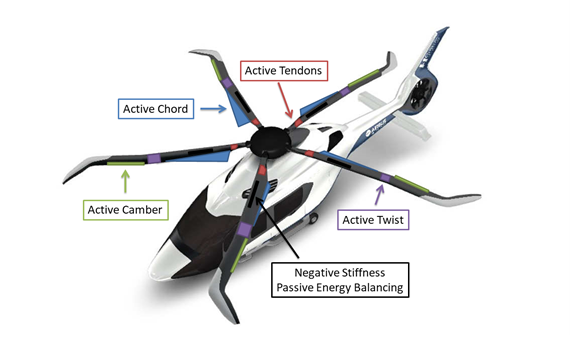

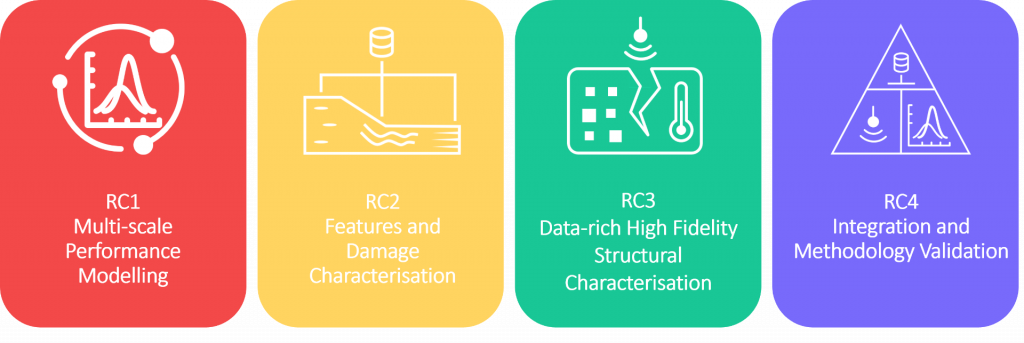

The aim of the research in this multidisciplinary project is to develop new approaches to enable lighter, more cost and fuel-efficient composite aero-structures. This vision will be realised through four flexible but highly interlinked research challenges:

- Multi Scale Performance Modelling

- Features and Damage Characterisation

- Data-rich High Fidelity Structural Characterisation

- Integration and Methodology Validation

The four research challenges will result in a new approach for integrated high-fidelity structural testing and multi-scale statistical modelling through Design of Experiments (DoE) and Bayesian Learning.

The efficient exploitation and optimisation of advanced composite aero-structures is fundamentally prohibited by current test, simulation and certification approaches, and CerTest seeks to break this impasse by holistically addressing the challenges that are preventing step-changes in future engineering design by reshaping the ‘Testing Pyramid’.

The CerTest project is supported by seven key industry partners who provide important steer and valuable market insight along with several funded studentships. Airbus, Rolls Royce, BAE Systems, GKN Aerospace, NCC, the Alan Turing Institute, and CFMS meet with the CerTest team at least twice a year and are keen to see the research succeed.

The project is further supported by an Independent Advisory Board of experts from international and UK based academia, industry and regulators that provide further guidance and support to ensuring CerTest reaches its full potential and realises its goals and objectives.

This is one of the largest collaborations the Bristol Composites Institute has ever undertaken, and a lot of groundwork has gone into supporting the collaboration, flow and sharing of data between the partners. The current CerTest team has 37 members and counting.

Further information

For more information and updates, visit the CerTest website.