by Siyuan Chen, Stephen Hallett and Jonathan Belnoue.

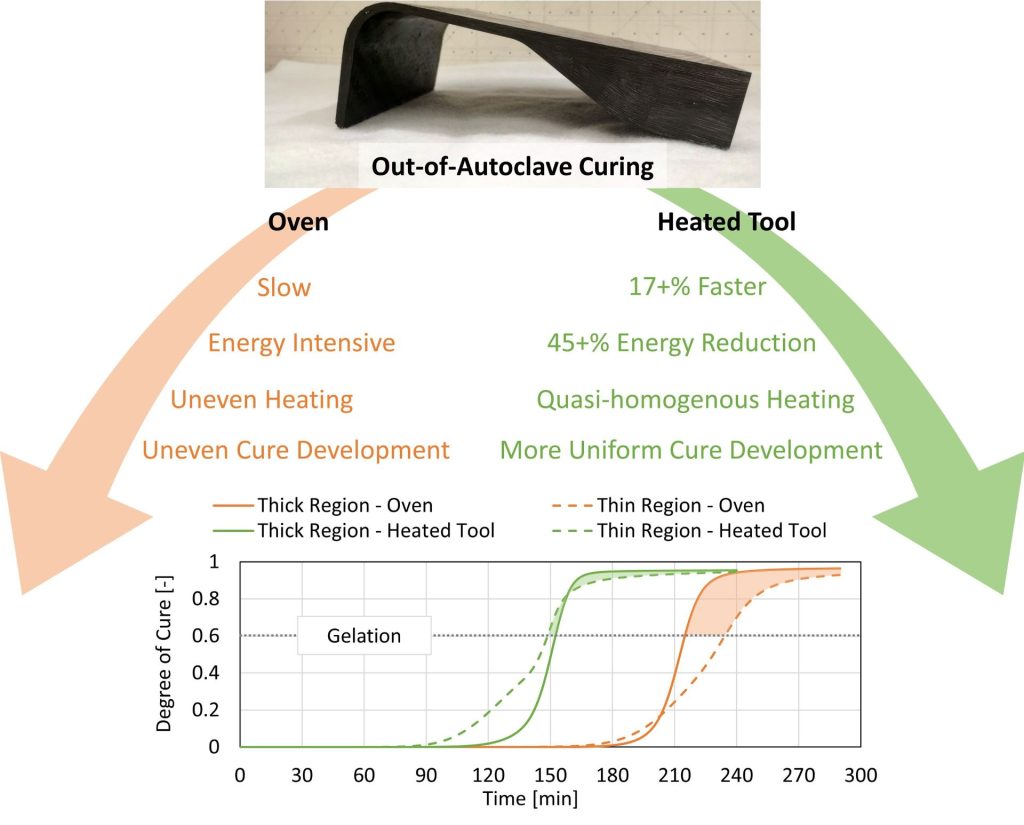

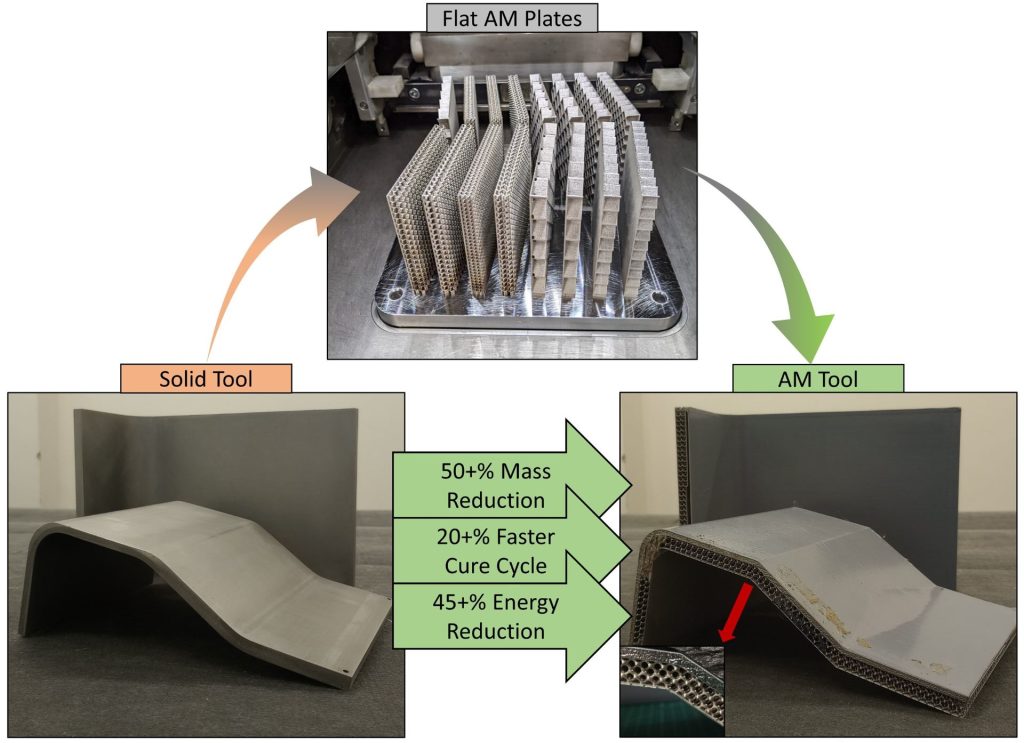

As the demand for carbon fibre-reinforced composites structures is rapidly growing, the industrial community continues to seek new manufacturing technologies that are low-defect, low-cost, highly efficient and environmental-friendly. Liquid molding is regarded as a cheaper alternative to the traditional prepreg/autoclave approach, however, the latter is often the favoured manufacturing route in the aerospace sector (where safety is paramount) as it allows for the production of better quality parts. One of the many challenges with infusion is the high deformability of the dry fibrous precursor materials that exposes the final structure to risks of defects and part to part variability. If the material and process (including their variabilities) are not controlled to a sufficient level, meeting design tolerances can prove challenging. These risks are traditionally mitigated through “over design” but this reduces a lot of the lightweighting advantages of using composites.

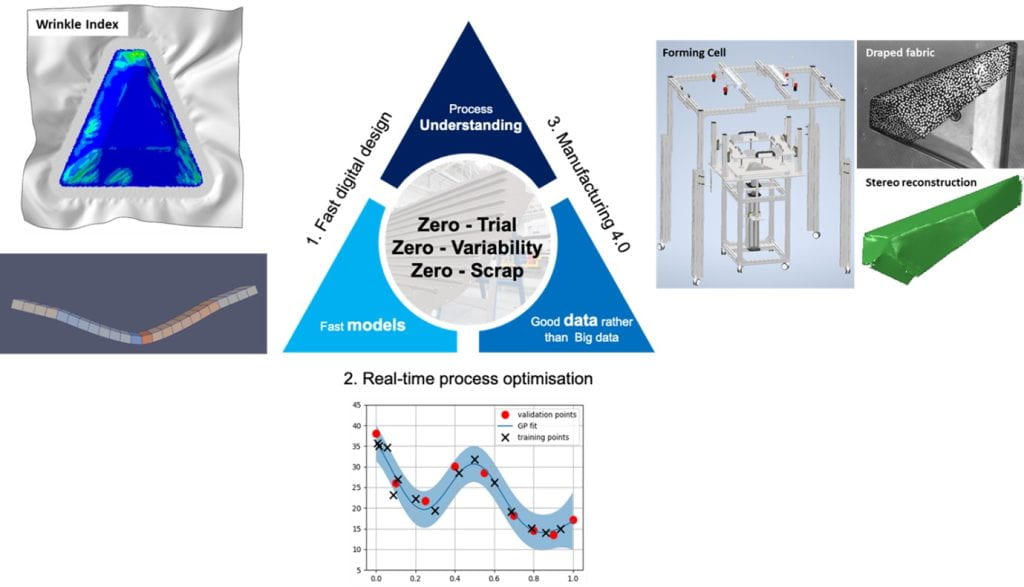

At BCI, we explore the possibility of achieving reduced-defect forming processes in 3 different ways. Firstly, design tools accounting for manufacturing constraint that are faster than current methods available commercially are being developed [1, 2]. These tools can be used to run moderate numbers (i.e., up to a 100) of simulations and allow to explore the impact of different combination of process control parameters on final part quality. This provide the possibility of optimising the forming process. The robustness of the optimisation is then improved by building Gaussian process (GP) emulator using the dataset produced using our fast simulation tools [3]. These GP emulators can achieve a good accuracy (error < 10%) and model the impact of several input parameters by running only tens of simulations. By introducing dimension reduction and active learning algorithms, the emulators can be expended to much more complex processes with over 10 input parameters [4]. After being trained, the emulators can also provide immediate predictions for final part quality. This open the door for digital twinning where in-process sensing and real-time simulation are combined. Thus, although forming processes can be optimised using deterministic FE simulations, real-world cases are affected by lots of factors such as material and process variability. Some of these variabilities are difficult to avoid but can be measured. Quantifying them (e.g., fibre direction misalignment, tow waviness, etc), a feedback loop whereby real-time simulations are informed by live data of the process and used to adapt the manufacturing condition to improve the final part quality can be set. A forming test cell instrumented with a stereo imaging system is currently being built in our labs. This will be used to construct a prototype digital twin for forming process.

To summarise, in our vision right first-time design and manufacture of composites can be achieved through a combination of (physics-based) digital design accounting for manufacturing constraints, fast process optimisation using data generated from process models and self-adapting manufacturing hardware controlled through emulators build from process models.

[1] Composites: Made Faster – Rapid, physics-based simulation tools for composite manufacture (ukri.org)

[2] JPH Belnoue, SR Hallett A rapid multi-scale design tool for the prediction of wrinkle defect formation in composite components, Materials & Design, 2020.

[3] S. Chen, A.J. Thompson, T.J. Dodwell, S.R. Hallett, J.P.-H. Belnoue, Fast optimisation of the formability of dry fabric preforms: A Bayesian approach, Materials & Design, 230:111986, 2023.

[4] S. Chen, A.J. Thompson, T. J. Dodwell, S.R. Hallett, J. P.-H. Belnoue. A Bayesian surrogate framework for the optimisation of high-dimensional composites forming process. In 5th International Conference on Uncertainty Quantification in Computational Science and Engineering, 2023.

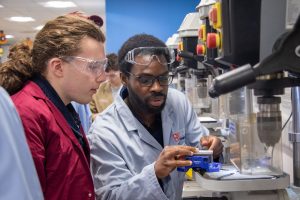

The pupils also used the pillar drills and laser cutter to create keychains that they could take home with them. Each pupil was also given the opportunity to spend time on the flight simulator, which was widely praised by the pupils.

The pupils also used the pillar drills and laser cutter to create keychains that they could take home with them. Each pupil was also given the opportunity to spend time on the flight simulator, which was widely praised by the pupils.